Digital Technologies for the Plastic Industry

– Plastic 4.0

24 September 2019

DTU Lyngby

Meeting Room 1

Anker Engelundsvej 1

2800 Lyngby

Are you ready to seize the opportunities and utilize current and future technologies related to Industry 4.0?

What solutions are available for injection molding and the plastic industry? What skills does it require? What new business models can be realized when the digital world and the physical world are integrated? How can digital technologies help to optimize time-to-market, quality, capacity and flexibility?

A number of leading companies will present Industry 4.0 technologies, solutions and applications. Speakers will present how different players and technology providers use Industry 4.0 concepts in the plastic industry and discuss opportunities and impact of digital technologies on processes and business models.

|

Registration and breakfast | |||

|

Welcome | |||

| Session 1 - Industry 4.0 Technologies for Injection Moulding | ||||

|

OPC UA – the global language for machines Marc Schmitt, Director Technology and Innovation, EUROMAP  Industry 4.0 means exchange of data/information between machines in order to increase the quality and efficiency of production. This is only possible with standardised interfaces. With machines and processes becoming increasingly complex, existing hardware interfaces are now reaching their limits. This is why EUROMAP develops new interfaces on the basis of OPC Unified Architecture (OPC UA). This platform ensures an independent interoperability standard, which secures a reliable exchange of data in the field of industrial automation in a number of industries. Marc Schmitt has been working for EUROMAP c/o VDMA plastics and rubber machinery for about 2 years. His main task is digitization, especially digital interfaces via OPC UA and platform economics. In his previous work, he dealt with the networking of machines and the implementation of ERP, MES and APS systems. |

|||

|

Inject 4.0 – where will digitalization bring smartness and change to injection moulding Jens Thor Hansen, CEO, Engel  The presentation will show where digital design has made it possible to make smart solutions and functionalities within machines (process and maintenance) and production management. This will be illustrated via a movie showing a high flexibility production cell, and a real case from DBI Plastics where the use of iQ weight control has improved product quality and significantly reduced scrap. Jens Thor Hansen has a degree in plastic engineering (PIFHT 1988) and has been working in the plastics industry for more than 30 years with an emphasis on medico and raw materials. Jens was most recently employed as VP R&D at AMBU, CEO at Knudsen Plast A/S, and for the last six years he has been responsible for ENGEL in the Nordic countries. |

|||

|

Inject 4.0 – where will digitalization bring smartness and change to injection moulding (continued) Jesper Rasmussen, Consultant, Engel  Jesper Rasmussen has a degree in plastic engineering and is a trained automation technician. Jesper has been working in the plastics industry for more than 25 years with an emphasis on process and mechanical engineering/robotics. Jesper was most recently employed as service technician at Andertech and Demag and as plastics processing operator at GN Resound and Corning Cabelcon. For the last eight years Jesper has been responsible for the sale of ENGEL machines and robots in Zealand/Funen and southern Jutland. Jesper Rasmussen has a degree in plastic engineering and is a trained automation technician. Jesper has been working in the plastics industry for more than 25 years with an emphasis on process and mechanical engineering/robotics. Jesper was most recently employed as service technician at Andertech and Demag and as plastics processing operator at GN Resound and Corning Cabelcon. For the last eight years Jesper has been responsible for the sale of ENGEL machines and robots in Zealand/Funen and southern Jutland. |

|||

|

WHY+HOW we have created and built a VERY LARGE 3D printfarm Erik Sten Andersen, CEO, Andertech, ADM-Factory and Ferromatik  This presentation will give an overview of how systematic use of ADM concept (Additive Design & Manufacturing) has helped us develop and produce one of the world’s first genuine AM based industrial products: CONRADT – a plastic material loader – that is produced in Denmark and distributed Globally. We give other companies access to our knowledge and huge print capacity (60+ printers) and we have increased tremendously the number of plastic parts you can print cheaper than by molding. Interesting case stories and plenty of examples. Erik Sten Andersen is CEO, founder and owner of Andertech, ADM-Factory/3D-Printfarm and Ferromatik. He has a degree in plastics engineering (PIFHT 1980) and have worked with plastics technology, automation and digitalization ever since (39 years). |

|||

|

Coffee Break | |||

|

Can MES be Anagram of SME? Giorgio Pigozzo, Manager for Digital Products, Wittmann-Battenfeld  The Manufacturing Execution Systems better known as MES have primarily been used in big or huge enterprises. But with the introduction of new “digital speaking production machines”, “internet of things” and affordable technologies from the IT industry, small and medium-aized enterprises are now reaping the benefits of big data analysis, production traceability and performance measurements. How is this possible? Interesting cases will be discussed. Giorgio Pigozzo holds a master degree in Aerospace Engineering (Politecnico di Milano). He began his career at AgustaWestland (now Leonardo Helicopters) focusing on Lean Engineering project. Now he is CEO and co-founder of ICE Srl, ICE Flex Srl and he is also collaborating with WittmannBattenfeld Gmbh as Manager for Digital Products. |

|||

|

Molding 4.0 - The Economics of an Injection Molding As-a-Service Business Model Guido Tosello, Associate Professor, Mechanical Engineering DTU  The impact of Industry 4.0 on the plastics industry will be analyzed in this talk with a focus on the injection molding technology. A new business model for the plastic industry is proposed, which fosters closer cooperation with suppliers and Internet-of-Things integration of equipment on the manufacturing company shop-floor. Automated quality control, predictive maintenance, and energy efficiency are identified as main levers of improvement, and associated cost savings are quantified. This study shows how the paradigm of Industry 4.0 is able to disrupt the industry by decreasing machine downtime and offering remarkable improvements in machine up-time. The present research aims at highlighting some of the opportunities for the plastic industry enabled by the implementation of an Internet of Things architecture. Guido Tosello has 10+ years of research experience in the analysis, characterization, monitoring, control, optimization and simulation of precision molding processes at micro/nano scales of thermoplastic materials. |

|||

| Session 2 - Sensor Technologies and Process optimization in the Digital Age | ||||

|

Online prediction – How to predict plastic part dimensions with pressure sensors and DoE Jani Laatikainen, Sales & Product Manager, Kistler Nordic AB  How to get 100 % production monitoring for injection molded plastic parts for certain quality features? Kistler have developed a measuring system what can predict your injection molded plastic part dimensions or quality features. The system requires process optimization software Stasa QC, a DoE bases software that links sensor information to DoE database. Jani Laatikainen is a specialist in injection molding who works at Kistler within the field of technical sales but also helps customers with quality related issues. |

|||

|

Lunch | |||

|

How to monitor and control new demanding materials in a networked production environment with the goal of 100% quality Konstantin Kraut, Deputy Head of Sales, Priamus System Technologies, branch of Barnes Group Suisse Industries LLC  Industry 4.0 and new demanding materials such as biopolymers and other materials with a high variation in viscosity are the current challenges customers have to face in a more and more networked production. Priamus shows possible solutions to control these challenging materials and processes by using cavity pressure and temperature sensors and how communication and data can be handled between injection molding machine, Priamus, MES System and other peripherals on a global scale. Konstantin Kraus is responsible for Priamus Switzerland's technical sales in Scandinavia including project management helping customers in quality relates issues. |

|||

|

How to use Digitalization in Profile Extrusion Dietman Gruber, Sales Director, extrunet GmbH Digitalization is a keyword for each industry, everybody is talking about Industry 4.0. |

|||

| Session 3 - Additive Manufacturing and Simulation for the Plastic Industry | ||||

|

LEAN Lifecycle Management – Seamless scalability from concept to commercialization Lasse Staal, CEO, AddiFab ApS  Hardware product development remains a challenge in spite of industry 4.0 advances. A lack of compatibility between prototyping and production platforms results in scalability challenges, and increased risks as manufacturers are forced to jump from prototyping to production. In this presentation, Lasse Staal will explain how Freeform Injection Molding (FIM) allows companies to move seamlessly between low and high-volume production in response to customer demands. By combining key benefits from AM and Injection Molding, FIM offers the same low start-up costs, short lead-times and design freedom as 3D-printers, but without constraints on materials and scalability. The result is LEAN Lifecycle Management: seamless scalability, extreme flexibility – and higher product lifecycle profits. Lasse Staal, co-founder of Danish start-up AddiFab, is an engineer turned entrepreneur with extensive hardware and software development experience. A passionate believer in the transformative potential of Additive Manufacturing (AM), he is equally passionate about removing the key limitations that prevent AM from becoming a cornerstone of global manufacturing. |

|||

|

Coffee Break | |||

|

iQtemp – the smart technology mix for conformal cooling Carlo Hüsken, Design Manager, Renishaw GmbH  iQtemp is a service brand of Renishaw GmbH and Listemann Technology AG for conformal cooling. It combines different technologies for conformal cooling such as additive manufacturing, vacuum brazing, and others for the best result. Focus on process reliability as well as maintainability of temperature control systems are key factors of this unique service. Lots of basic information about conformal cooling, practical examples of full series production and an interesting case study offer an excellent impression of state of the art in modern conformal cooling. Quality of the cooling liquid and corrosion in the cooling channels are the main challenges for customers and will also be addressed in the presentation. Carlo Hüsken, a certified engineer with 12 years' experience in conformal cooling and 39 years´ experience in mold making and injection molding, is responsible Design Manager at Renishaw GmbH, Germany for additive manufacturing and conformal cooling. He also lectures at the Technical University Schmalkalden in conformal cooling in additive manufacturing. |

|||

|

Digital manufacturing at HP Inc. Nuno Almeida, Application Engineer, Hewlett Packard  This talk will present various use cases in both thermoplastics and metals printers. It will also show how the technology works and how HP leverages its own technology in various other businesses. Nuno Ricardo Almeida is a MSc. Mechanical Engineer with more than 10 years’ experience within Research/Product/ProjectDevelopment, 3D CAD concept design, Additive Manufacturing and Engineering Analysis (FEA and CFD). He had previously work in companies like FMC Technologies, GE, Danfoss and he believes that Additive Manufacturing will disrupt the way we produce things. |

|||

|

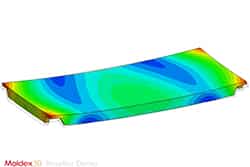

Virtual product development using Moldex3D Injection Molding Simulation Peer Guldbrandsen, Managing Director, Flowhow  During the last 5-10 years, simulation tools for the plastic industry have matured and are so easy to use that even small companies without 100% dedicated resources may have development processes that include simulation. Including simulation in your development processes will lead to fulfilling your quality specifications in the first molding attempt without delays. With injection Molding simulation you can determine the correct wall thicknesses, gate position, runner dimensions, cooling layout etc., and obtain higher quality products at a lower price in less time. A strategy for simulations is a part of Industry 4.0. Examples and suggestions for working processes are part of this presentation. Peer Guldbrandsen is Owner and Managing Director of FlowHow. He has more than 35 years of experience in the plastic industry and has been working with simulation and problem solving for more than 25 years. |

|||

|

Closing remarks |

Registration fee

Members of ATV-SEMAPP or other promoting organizations: DKK 2,150

Non-members: DKK 2,775

M.Sc. students: DKK 200 & Ph.D. students: DKK 975 (Membership is free of charge. Early bird discount does not apply)

All prices are exclusive of 25 % VAT.

Early bird discount of DKK 200 when registering before 23 August 2019.

Members of ATV-SEMAPP or other promoting organizations: DKK 2,150

Non-members: DKK 2,775

M.Sc. students: DKK 200 & Ph.D. students: DKK 975 (Membership is free of charge. Early bird discount does not apply)

All prices are exclusive of 25 % VAT.

Early bird discount of DKK 200 when registering before 23 August 2019.

The fee includes talks, breakfast, lunch and coffee breaks.

Binding registration

Registration is binding, however substitutions are accepted at any time.

Questions

Please do not hesitate to contact ATV-SEMAPP by e-mailing semapp@atv-semapp.dk or phoning Jytte Laursen +45 4525 4898 or Charlotte Leser +45 4525 4899.